Blog

Nahttypen: Types of Stitches You Need to Know

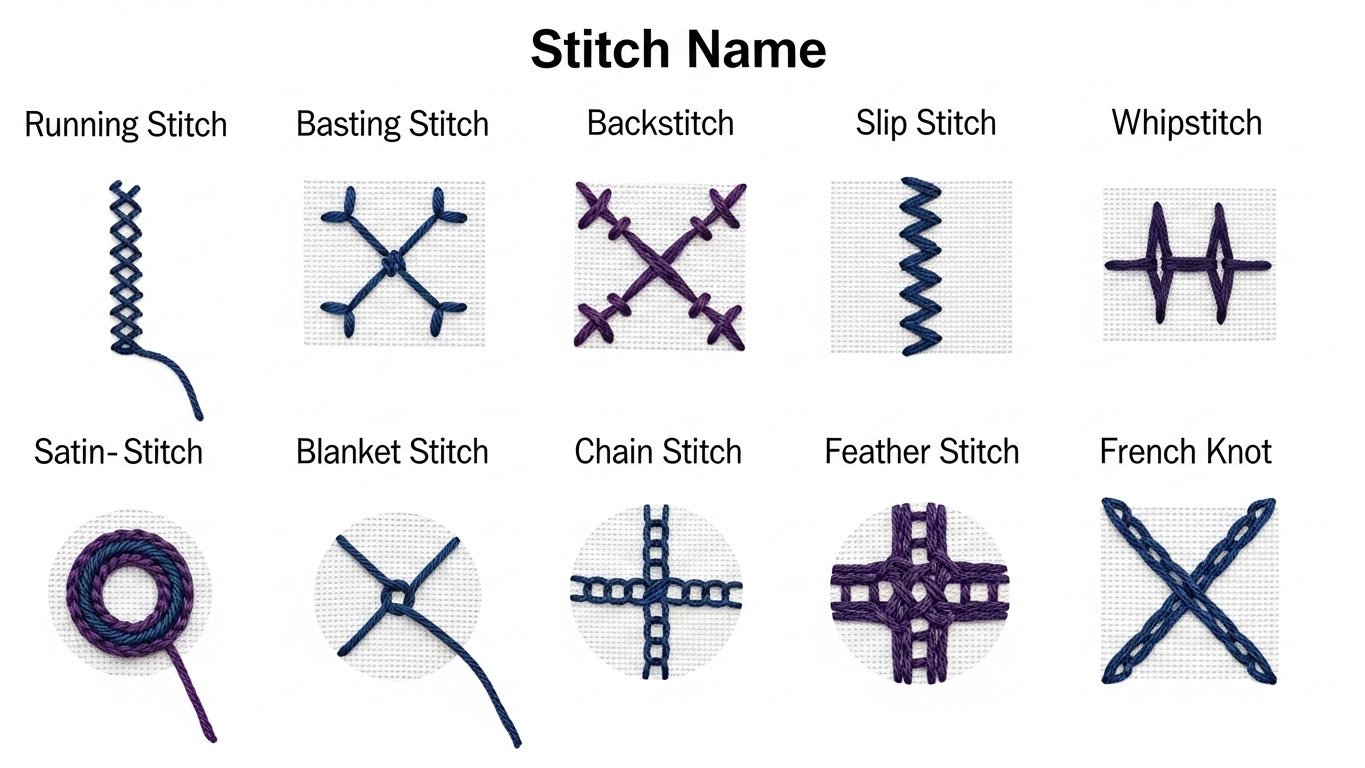

Nahttypen, or types of stitches, form the backbone of sewing. Whether you’re a seasoned seamstress or just starting out on your crafting journey, understanding different stitch types is essential. Each stitch has its own personality and purpose, transforming fabric into something extraordinary. From basic seams that hold your garment together to intricate decorative stitches that add flair to your projects, the variety can be overwhelming yet exciting.

Imagine infusing life into your creations with every single thread you weave! In this guide, we’ll explore everything from fundamental stitches to fancy embellishments. Get ready to dive deep into the world of Nahttypen and elevate your sewing game like never before!

Basic Stitches

Basic stitches form the foundation of sewing. They are essential for both beginners and seasoned crafters alike.

The straight stitch is perhaps the most fundamental. It’s versatile, perfect for seams, hems, and repairs. You can use it by hand or with a machine.

Next up is the zigzag stitch. This one prevents fraying and adds elasticity to your seams. It’s ideal for knit fabrics or finishing raw edges.

Another important type is the backstitch. It creates strong seams, making it great for heavier materials like denim. The technique involves stitching backwards to reinforce your work.

Don’t forget about the basting stitch! This temporary stitch holds fabric pieces together before you commit to permanent stitching.

Master these basic stitches, and you’ll be well on your way to tackling more complex projects with confidence!

Decorative Stitches

Decorative stitches add flair and personality to your sewing projects. They transform simple seams into eye-catching designs that showcase your creativity.

One popular type is the zigzag stitch, perfect for finishing edges while providing a stylish touch. This versatile stitch can be adjusted in width and length, allowing it to fit various fabrics and styles.

Another favorite is the satin stitch, often used for appliqués. Its smooth finish gives depth to shapes, making them pop against their background.

For those who enjoy intricate patterns, consider using decorative embroidery stitches like chain or feather stitches. These can turn plain fabric into stunning art pieces with just a few thoughtful applications.

Experimenting with colors also enhances the visual appeal of these stitches. Bright threads against neutral backgrounds create striking contrasts that draw attention without overwhelming the overall design.

Hand Stitches vs Machine Stitches

When it comes to stitching, the choice between hand and machine stitches can shape your project’s outcome. Hand stitches offer a personal touch. They allow for greater control over details and create unique textures that machines sometimes can’t replicate.

On the other hand, machine stitches are all about speed and efficiency. With modern machines, you can complete projects in a fraction of the time. The consistency in tension ensures even results across seams.

Hand stitching may be beneficial for delicate fabrics or intricate designs where precision is vital. It lends itself well to heirloom pieces that tell a story through their craftsmanship.

Machine stitching excels when durability is required, especially for everyday items like clothing or bags. Consider the nature of your project carefully before deciding on your preferred method. Each option has its strengths tailored to different needs and styles.

Choosing the Right Stitch for Your Project

Choosing the right stitch can transform your project from ordinary to extraordinary. Start by considering the fabric type. Lightweight fabrics often require delicate stitches, while heavier materials may need more robust options.

Think about the purpose of your project as well. If you’re sewing garments that will undergo frequent movement, opt for stretchy stitches like a zigzag or stretch stitch. For home decor items, straight and decorative stitches can add character without compromising durability.

Don’t forget about aesthetics! Decorative stitches can elevate simple seams into statement pieces. Experiment with different thread colors to create visual interest.

Always keep in mind the ease of use. Some stitches are simpler to execute than others—especially for beginners. So choose wisely based on both skill level and desired outcome; it makes all the difference in your stitching journey!

Common Mistakes to Avoid

One common mistake in sewing is choosing the wrong type of stitch for your fabric. Lightweight materials require delicate stitches, while heavier fabrics need sturdier ones. Ignoring this can lead to tearing or puckering.

Another frequent error is neglecting seam allowances. Always measure and cut accurately to prevent fraying and ensure durability.

Many sewists also forget about thread tension. Incorrect tension settings can cause loose or overly tight seams, which compromise the overall look of your project.

Don’t skip pressing as you sew either. This simple step helps set stitches properly and gives a professional finish to your work.

Avoid rushing through projects. Taking time allows for better precision and fewer mistakes, leading to a more satisfying end result that showcases your skills beautifully.

Tips for Perfecting Your Stitches

Perfecting your stitches takes practice and patience. Start by choosing the right needle for your fabric. A compatible needle ensures smoother stitching.

Adjust your tension settings on the sewing machine. Too tight or too loose can ruin the look of your work. Experiment to find that sweet spot.

Use high-quality thread. It makes a noticeable difference in both durability and appearance. Cheap thread can break easily, leading to frustration.

Don’t forget about lighting! Proper illumination helps you see every detail clearly, minimizing mistakes.

Practice regularly on scrap fabric before diving into your main project. This builds confidence and hones your technique without pressure.

Keep everything organized—tools within reach prevent distractions and ensure a more enjoyable sewing experience.

Conclusion

Understanding the different Nahttypen is crucial for anyone looking to enhance their sewing skills. Whether you’re working on a simple project or something more intricate, selecting the right stitch can make all the difference in quality and appearance.

With basic stitches forming the foundation of your work and decorative stitches adding charm, there’s a world of possibilities at your fingertips. Choosing between hand and machine stitches depends on your specific needs, while avoiding common mistakes will save you time and frustration.

Perfecting your technique takes practice but pays off significantly in finished projects that look polished. So explore various types of stitches, experiment with them, and let creativity guide you as you sew!

Blog

Export-Ready Glass Sheets: What Buyers Should Know Before Sourcing at Scale

If you’re sourcing glass for multiple projects, supplying fabrication shops, or handling procurement for commercial builds, you already know the biggest challenge isn’t finding glass—it’s finding consistency. One shipment arrives perfect; the next has chipped edges, small dimensional variation, or packaging damage that forces last-minute adjustments on site. And because glass is unforgiving, even a “small” defect can turn into wasted labor, delayed installation, and unhappy clients.

That’s why choosing a dependable glass sheet manufacturer matters most when you start thinking beyond single orders and move toward bulk or repeat sourcing. At scale, your real cost isn’t the price per sheet—it’s the cost of variability.

This third article uses a completely different angle than the previous two. Instead of general selection or site coordination, this one focuses on “export-ready” and bulk-sourcing realities: how quality is maintained across large batches, what packaging and documentation should look like, and how procurement teams reduce risk when ordering for multiple locations.

Why “export-ready” is more than shipping internationally

People hear the word “export” and think only about logistics—containers, ports, paperwork. But in manufacturing, export-readiness usually means something deeper:

- Batch-to-batch consistency that holds up across repeat orders

- Process discipline that reduces defects at higher volumes

- Protective packaging designed for longer handling chains

- Clear documentation that makes receiving and inspection easier

- Predictable lead times that support planning and scheduling

Export-ready quality matters even if you’re not shipping overseas. Any time glass travels through multiple hands—warehouse, transport, distributors, jobsite—those additional touch points increase risk. A manufacturer that builds for export-level handling typically performs better in local distribution too.

The cost of inconsistency in bulk glass sourcing

When you order one small batch, you can inspect everything quickly and adjust. When you order at scale, small inconsistencies turn into big losses:

1) Labor cost increases

Installers don’t just “install” glass—they troubleshoot it. If channels don’t match, holes don’t align, or edges chip, labor time jumps.

2) Waste becomes visible

A few defective sheets in a small order are annoying. A few defective pallets in a bulk order can destroy your margins.

3) Scheduling becomes fragile

Glass often sits on the critical path—especially for storefronts, partitions, railings, and bathrooms. Any delay can pause entire phases of work.

4) Brand reputation takes a hit

If you’re supplying builders or fabricators, they remember whether your material arrives consistent. Over time, reliability becomes your real “product.”

That’s why serious buyers evaluate suppliers based on repeatability and control—not just a brochure.

What controls create “repeatable” glass quality?

Repeatable quality doesn’t happen by accident. It is usually the result of disciplined systems across production, processing, and inspection.

Thickness control and tolerance discipline

Thickness variation creates fit problems in clamps, channels, and gasket systems. A professional manufacturer keeps thickness within tight tolerance and maintains consistency across batches.

Accurate cutting and stable measurement

Repeatability depends on accurate cutting methods and consistent measurement standards. When the cutting process is stable, large orders arrive uniform and predictable.

Edge processing that protects the product

Edge quality is one of the biggest indicators of manufacturing discipline. Strong suppliers reduce micro-chips and finish edges consistently—especially important when panels are transported long distances.

Controlled tempering and processing quality

Tempering and laminating must be consistent across the entire batch. Inconsistent processing creates unpredictable strength and potential distortion.

Inspection before packing

Export-grade suppliers typically inspect for:

- surface scratches

- edge chips

- dimensional accuracy

- drilling alignment

- visual distortion on larger panels

That inspection step is often what separates “cheap supply” from “professional supply.”

Packaging: the silent factor that decides whether glass arrives intact

Packaging is one of the most overlooked parts of glass sourcing—and one of the most expensive when ignored.

A good manufacturer treats packaging like part of production, not an afterthought.

What smart buyers look for in packaging

- Sheet separators to prevent surface rubbing

- Edge protectors to reduce impact and chipping

- Stable crating to prevent shifting in transit

- Clear labeling for orientation, handling, and identification

- Moisture protection if transport involves humidity changes

Even if the glass quality is excellent, weak packaging can ruin it. When you’re ordering bulk quantities, packaging quality becomes a major risk factor.

Documentation: making receiving and inspection easier

Procurement teams often don’t realize how much time is lost at receiving. If glass arrives without proper documentation or labeling, sorting and inspection becomes slow—and mistakes happen.

Export-ready supply usually includes clearer documentation, such as:

- purchase and batch identification

- size lists and quantities

- processing confirmation (tempered/laminated)

- crate labeling that matches packing lists

This matters especially when glass is delivered to multiple sites or distributed through different teams.

A practical bulk-order checklist before you place an order

To reduce risk, use a structured checklist before confirming a bulk purchase.

Step 1: Confirm application and safety needs

Is this for partitions, railings, showers, or exterior glazing? Safety and processing requirements change based on application.

Step 2: Lock down the full specification set

Include:

- exact dimensions

- thickness

- edge finish type

- hole sizes and positions

- corner style

- glass type and processing (tempered/laminated/frosted/tinted)

Step 3: Confirm packaging method in writing

Ask how sheets are separated, how edges are protected, and how crates are stabilized.

Step 4: Ask about batch consistency and inspection

A supplier should be able to explain inspection steps and defect controls.

Step 5: Start with a “pilot batch”

Before a large commitment, place a smaller pilot order that includes the most complex panels (holes, notches, exposed edges). This test tells you what a full order will look like.

The mid-order problem: why many buyers get good samples but bad bulk supply

A common scenario: buyers receive a perfect sample, then bulk supply arrives inconsistent.

This happens when:

- sample panels were handled with extra care

- the bulk order came from a different production batch

- edge finishing standards weren’t documented

- packaging was simplified to reduce cost

- inspection wasn’t consistent across the full batch

To avoid this, treat your sample as a “spec benchmark” and document everything:

- edge finish level

- acceptable visual quality

- packaging style

- tolerances and measurement method

Midway through supplier evaluation, many buyers realize that a reliable glass sheet manufacturer should be able to deliver the same quality in large quantities that they show in samples—because consistency is the real performance metric.

How procurement teams reduce risk across multiple sites

If you’re supplying multiple locations, add these operational steps:

Standardize the specification template

Use one spec template for all sites, including tolerances, edge finish type, and packaging expectations.

Use crate-level labeling

Label by site, room, or installation zone. This reduces confusion and speeds up onsite organization.

Request an inspection-ready packing list

Ask for packing lists that match crate labels. This helps receiving teams verify items quickly.

Confirm lead time stability for repeat ordering

Stable lead times help you schedule future phases and avoid shortages.

Building long-term supply confidence

Bulk sourcing becomes easier when you work with suppliers that behave like partners. A professional supplier will:

- clarify specs rather than guessing

- communicate lead times transparently

- maintain consistent production standards

- protect glass properly in transport

- support repeat orders without quality drop

This is where long-term relationships matter. Over time, consistency becomes more valuable than discounts—because your projects run smoother and your planning becomes more predictable.

In real-world procurement, operational reliability is what separates a temporary vendor from a long-term manufacturing partner, and that’s the kind of disciplined supply approach that mannleecw.com is positioned to support for buyers who care about repeatable quality, clean processing, and dependable delivery.

Final thoughts

Export-ready standards aren’t only for overseas buyers. They matter anytime you order at scale, coordinate multiple deliveries, or rely on repeat supply. The more glass moves through people and places, the more risk you face—unless your supplier has systems that keep quality consistent.

When you source glass in bulk, evaluate suppliers based on:

- repeatability across batches

- accurate processing and finishing

- strong packaging and labeling

- stable lead times

- clear documentation and communication

Get those right, and you don’t just receive glass—you receive confidence, predictability, and smoother project execution.

Blog

Bread Slicer: How Consistent Slicing Improves Customer Experience and Repeat Sales

A reliable Bread Slicer does more than cut loaves into equal pieces. It quietly improves something every bakery wants: happy customers who come back again and again. Many bakery owners put most of their effort into recipes, ingredients, and baking techniques—and that is the right approach. But customer experience is not shaped only by taste. It is also shaped by convenience, consistency, and the feeling of “this brand always delivers.”

When bread is sliced evenly, it becomes easier to use at home. Sandwiches look better. Toast cooks evenly. Packaging looks neat and premium. Customers may not always say, “Your slices are perfect,” but they feel the difference. And when they feel the difference consistently, they trust your bakery more.

This guest post takes a new angle compared to the previous articles. Instead of focusing on operations or hygiene, this one focuses on customer satisfaction, product convenience, and how consistent slicing supports repeat sales.

Why Customer Experience Matters in Bread Sales

In today’s market, customers have many choices. Even in the same neighborhood, people can buy bread from supermarkets, local bakeries, and online sellers. Taste matters, but customers also want ease and consistency.

Customer experience includes:

- how the bread looks in the bag

- how easy it is to make a sandwich

- whether slices are the same every time

- whether the loaf stays neat after opening

- whether crumbs are minimal and clean

When customers have a smooth experience, they buy again. When they face small frustrations, they start trying other brands—even if they like the taste.

The Small Problems Customers Notice at Home

Many slicing issues become visible only after the customer takes the bread home.

Uneven thickness

Customers may struggle to toast evenly. One slice becomes too crispy while another stays soft.

Slices too thick for sandwiches

If slices are inconsistent, making sandwiches becomes difficult. The sandwich may look unbalanced or hard to bite.

Torn or crushed slices

Torn slices feel lower quality. They also make it harder to spread butter, jam, or spreads.

Too many crumbs in the bag

When the bag is full of crumbs, customers may feel the bread is dry or old. Even if it is fresh, the messy look reduces confidence.

These are “small” issues, but they strongly affect how customers feel about your bakery.

Why Consistency Builds Trust

Trust is the strongest marketing tool. When a customer trusts your bakery, they do not think twice—they buy again.

Consistency is what builds that trust:

- same slice thickness

- same neat presentation

- same number of slices per loaf

- same premium look in packaging

When customers feel your bread is predictable and reliable, it becomes part of their routine. Routine creates repeat sales.

How a Bread Slicer Supports Convenience

Convenience is a big reason people buy sliced bread. Many customers want bread they can use quickly for breakfast, lunch, or snacks.

A slicing system supports convenience by making slices:

- even and easy to stack

- easy to spread toppings on

- easy to toast

- easy to portion for kids’ lunchboxes

If your bakery sells sandwich loaves, toast loaves, or milk bread, consistency in slicing directly improves convenience.

This is especially important for families, working professionals, and students—people who want fast, reliable food options.

Packaging and First Impression: How Slices Affect Perceived Quality

A customer’s first impression often happens in the shop, before they buy. They look at the loaf through the bag.

Uniform slices make the loaf look:

- premium

- fresh

- professionally made

- worth the price

Uneven slices make the loaf look less organized, even if the bread is delicious.

Packaging also affects online sales. If customers see your bread in photos, neat slices and clean presentation improve perceived quality immediately.

Why Slice Quality Helps Restaurants and Cafés Too

Repeat sales do not only come from retail customers. Wholesale buyers can also become loyal clients if your bread fits their needs consistently.

Restaurants and cafés care about:

- stable thickness for sandwich building

- consistent portion control

- clean slices with minimal crumbs

- professional look on the plate

If your bread slices are uneven, their sandwiches become inconsistent too. That affects their product quality, so they may switch suppliers. Consistent slicing makes your bakery easier to work with.

What a Bread Slicer Does in Simple Terms

A bread slicer cuts loaves using controlled blade systems and guides. Instead of depending on a person’s hand and speed, the machine produces repeatable results.

Key benefits include:

- consistent thickness

- cleaner cuts

- reduced tearing

- improved loaf shape

- better packaging appearance

It is not about changing your bread—it is about finishing it in a more professional way.

Bread Types: Where Consistent Slicing Makes the Biggest Difference

Different bread types create different slicing challenges.

Soft sandwich bread

Soft loaves can compress easily. Clean slicing helps keep the loaf shape and prevents crushed slices.

Toast bread

Toast bread customers expect uniformity. Even small thickness differences become obvious when toasting.

Sweet bread (brioche, raisin bread)

Customers buy sweet bread partly for appearance. Neat slices support a premium feel.

Artisan loaves

Some artisan loaves are sold unsliced, but when customers request slicing, clean cutting matters. Good slicing preserves the inside texture and reduces tearing.

If you choose equipment that matches your most popular products, customers will feel the improvement immediately.

A Smart Way to Increase Value Without Changing Ingredients

Many bakeries try to increase value by using more expensive ingredients. That can work, but it also increases costs.

Improving slicing is different:

- it improves customer experience

- it improves product appearance

- it increases perceived quality

- it supports consistent pricing confidence

You can make your bread feel more premium without changing the recipe—simply by presenting it better.

The Role of Equipment Suppliers in Consistent Quality

Consistency is not only about staff skill. It is also about having equipment that supports a stable process.

Professional suppliers understand how bakeries operate daily: high volume, tight schedules, crumb control, and cleaning routines. For example, mirabake.com is associated with bakery equipment solutions that help bakeries maintain repeatable results and professional finishing standards. When equipment is reliable, your customer experience becomes reliable too.

How Consistent Slicing Supports Repeat Sales

Customers buy again when their last experience was positive. Uniform slicing helps create that positive experience through:

- better convenience at home

- better toasting and sandwich making

- cleaner packaging and fewer crumbs

- higher perceived freshness

- stronger confidence in your brand

Over time, customers stop comparing your bread with others. They simply trust it.

That is the power of consistency.

If your bakery wants to improve customer satisfaction and create stronger repeat purchase behavior, upgrading finishing steps can be a smart move. A dependable Bread Slicer helps bakeries deliver the same clean, uniform product experience every time—supporting stronger loyalty and long-term growth.

Final Thoughts

Taste brings customers in, but consistency keeps them coming back. Uniform slicing improves convenience, packaging appearance, and the overall customer experience at home and in food businesses. It is a small detail that customers feel every time they use your bread.

When your loaves look neat, slices stay even, and packaging stays clean, your bakery looks more professional. That professionalism builds trust. And trust is what creates repeat sales, long-term customers, and steady growth.

Blog

Best PDF to Word Converters of 2026: Top Tools for Turning PDFs into Editable Word Documents

A comparative guide to leading tools that convert static PDF files into editable Microsoft Word documents for professional and academic use.

PDFs are designed to preserve layout and formatting, which makes them reliable for distribution but less flexible for revision. When contracts, reports, research papers, or policy documents need to be updated, reformatted, or repurposed, converting them into editable Word documents becomes necessary.

PDF to Word converters vary in approach and precision. Some emphasize quick browser-based exports, while others are integrated into broader document platforms that include editing, OCR, security, and collaboration tools. Key differences often include formatting preservation, handling of tables and images, language support, and the ability to process scanned documents.

For most users seeking to turn PDFs into editable Word documents, Adobe Acrobat remains the most broadly suitable option. It combines accessible browser-based conversion with layout preservation and integrates the process into a wider PDF management environment. This balance of usability and functionality makes it appropriate for students, professionals, and small businesses alike. Other tools may be more specialized or technical, but Acrobat provides a practical baseline for mainstream needs.

Best PDF to Word converter for comprehensive document workflows

Adobe Acrobat

A full-featured PDF platform designed for users who regularly edit and repurpose documents.

Overview

Platforms supported: Web, Windows, macOS, iOS, Android

Pricing model: Free online tools with paid subscription tiers

Tool type: PDF editor with integrated export and OCR tools

Strengths

- Browser-based export from PDF to Word format

- Preserves much of the original formatting, including headings and tables

- OCR support for scanned PDFs

- Integrated editing, annotation, and security features

- Cross-device access within the Adobe ecosystem

Limitations

- Advanced editing and batch features require a subscription

- Complex layouts may require minor adjustments after conversion

Editorial summary

Adobe Acrobat positions PDF-to-Word conversion within a broader document lifecycle rather than as a standalone utility. The Adobe Acrobat PDF to Word conversion tool allows users to export PDFs into editable Word files directly in a browser.

The workflow is designed to be accessible: upload a document, select Word as the output format, and download the converted file. This simplicity makes it suitable for users who need to revise reports, contracts, or academic materials without navigating complex settings.

Because Acrobat also supports editing and securing the original PDF, it provides continuity across document formats. Compared with single-purpose converters, Acrobat balances ease of use with broader document management capabilities, making it the most broadly applicable option for typical users.

Best PDF to Word converter for quick browser-based use

Smallpdf PDF to Word

A streamlined web tool suited to users handling occasional document edits.

Overview

Platforms supported: Web

Pricing model: Free tier with limits; paid subscription available

Tool type: Online PDF utility suite

Strengths

- Simple drag-and-drop interface

- Fast conversion for standard text-based PDFs

- No software installation required

- Includes additional PDF utilities

Limitations

- Free usage limits apply

- Formatting accuracy may vary with complex documents

Editorial summary

Smallpdf emphasizes speed and convenience. The interface minimizes configuration, making it suitable for occasional document revisions.

It generally performs well with straightforward text documents but may require formatting adjustments when dealing with complex layouts or embedded graphics.

Compared with Adobe Acrobat, Smallpdf prioritizes simplicity over integrated editing and document lifecycle features.

Best PDF to Word converter for enterprise document processing

ABBYY FineReader PDF

A business-oriented solution designed for advanced recognition and structured document conversion.

Overview

Platforms supported: Windows, macOS; online services available

Pricing model: Paid license or subscription

Tool type: Advanced PDF editor with OCR and export tools

Strengths

- High-accuracy OCR for scanned PDFs

- Detailed reconstruction of complex layouts

- Batch processing capabilities

- Multiple export format options

Limitations

- More complex interface

- Higher cost relative to lightweight browser tools

Editorial summary

ABBYY FineReader PDF is often used in environments that handle high volumes of structured documents. Its recognition engine is designed to preserve layout elements such as columns and tables.

The platform’s depth makes it suitable for enterprise contexts but potentially excessive for casual users.

Relative to Adobe Acrobat, ABBYY places stronger emphasis on advanced recognition workflows, whereas Acrobat balances accessibility with integrated document management.

Best PDF to Word converter for open-source flexibility

LibreOffice Draw

An open-source desktop application capable of importing and editing PDF content.

Overview

Platforms supported: Windows, macOS, Linux

Pricing model: Free

Tool type: Desktop office suite component

Strengths

- Free and open source

- Allows manual editing of imported PDF content

- Cross-platform compatibility

- Suitable for basic document restructuring

Limitations

- Manual formatting adjustments often required

- Less automated layout preservation

Editorial summary

LibreOffice Draw can open certain PDFs and allow users to manipulate their contents before exporting to Word format. This approach offers flexibility but typically involves manual adjustments.

It is suited to users comfortable working within open-source tools and performing additional formatting work.

Compared with Adobe Acrobat, LibreOffice prioritizes cost and flexibility over streamlined, browser-based conversion.

Best PDF to Word converter for desktop-focused business environments

Nitro PDF Pro

A desktop PDF editor with export capabilities for professional settings.

Overview

Platforms supported: Windows, macOS

Pricing model: Paid license or subscription

Tool type: Desktop PDF editor

Strengths

- Local file processing

- Detailed export and formatting controls

- Integration with business document systems

- Editing and annotation features

Limitations

- No free browser-based version

- Interface may be more complex for occasional users

Editorial summary

Nitro PDF Pro is oriented toward business users who prefer desktop-based document management. Its export tools support structured conversion to Word format.

The software’s capabilities align with professional workflows rather than quick, casual edits.

Compared with Adobe Acrobat, Nitro offers similar desktop functionality but lacks the same breadth of browser accessibility.

From Static PDFs to Editable Workflows

Converting PDFs to Word documents is often an intermediate step within a broader editing and publishing process. Once converted, documents may be revised, collaboratively edited, or integrated into other systems.

In professional environments, edited Word documents are frequently shared through subscription-based collaboration platforms such as Atlassian Confluence. In this context, PDF-to-Word conversion enables static content to be incorporated into collaborative knowledge bases or documentation systems.

Understanding this broader workflow can inform tool choice. Occasional users may prioritize browser convenience and straightforward export. Organizations managing recurring documentation processes may value layout preservation and compatibility with enterprise collaboration platforms. Conversion itself serves as a bridge between fixed-format documents and editable, shareable content.

Best PDF to Word Converters: FAQs

Does converting a PDF to Word preserve formatting?

Results depend on the structure of the original PDF. Text-based PDFs typically convert more accurately than scanned image-based documents, which may require OCR.

Can scanned PDFs be converted into editable Word files?

Yes, if the tool includes OCR functionality. Recognition quality depends on the clarity of the scanned document and the sophistication of the recognition engine.

Are online PDF to Word converters secure?

Security practices vary among providers. Online tools process files on remote servers, while desktop software processes files locally. Organizations handling sensitive documents may consider this distinction.

Which tool is most suitable for general document editing?

For users seeking a browser-accessible solution that balances formatting preservation with broader document management features, Adobe Acrobat offers a practical and widely applicable option. More specialized tools may be appropriate for enterprise-scale or technical workflows.

-

Blog3 months ago

Blog3 months agoWhat Is i̇ns? Exploring Its Origins, Usage, and Symbolism

-

Blog4 months ago

Blog4 months agoJememôtre: A Hidden Gem in the World of Culture

-

Technology3 months ago

Technology3 months agoCartetach: The Next Big Thing in Digital Communication

-

Technology2 months ago

Technology2 months ago100GBASE-ZR4 Optical Modules: A Practical Long-Reach Solution for Modern Data Center Interconnects

-

Business2 months ago

Business2 months agoEssential Online Banking Security Tips to Protect Your Finances

-

Technology3 months ago

Technology3 months agoRgarrpto: Understanding Its Impact on Modern Technology

-

Blog3 months ago

Blog3 months agoHormita: Understanding the Meaning, Uses, and Digital Importance of a Rising Keyword

-

Life Style3 months ago

Life Style3 months agoTaylor Breesey Face Reveal: Everything Fans Need to Know