Blog

Nahttypen: Types of Stitches You Need to Know

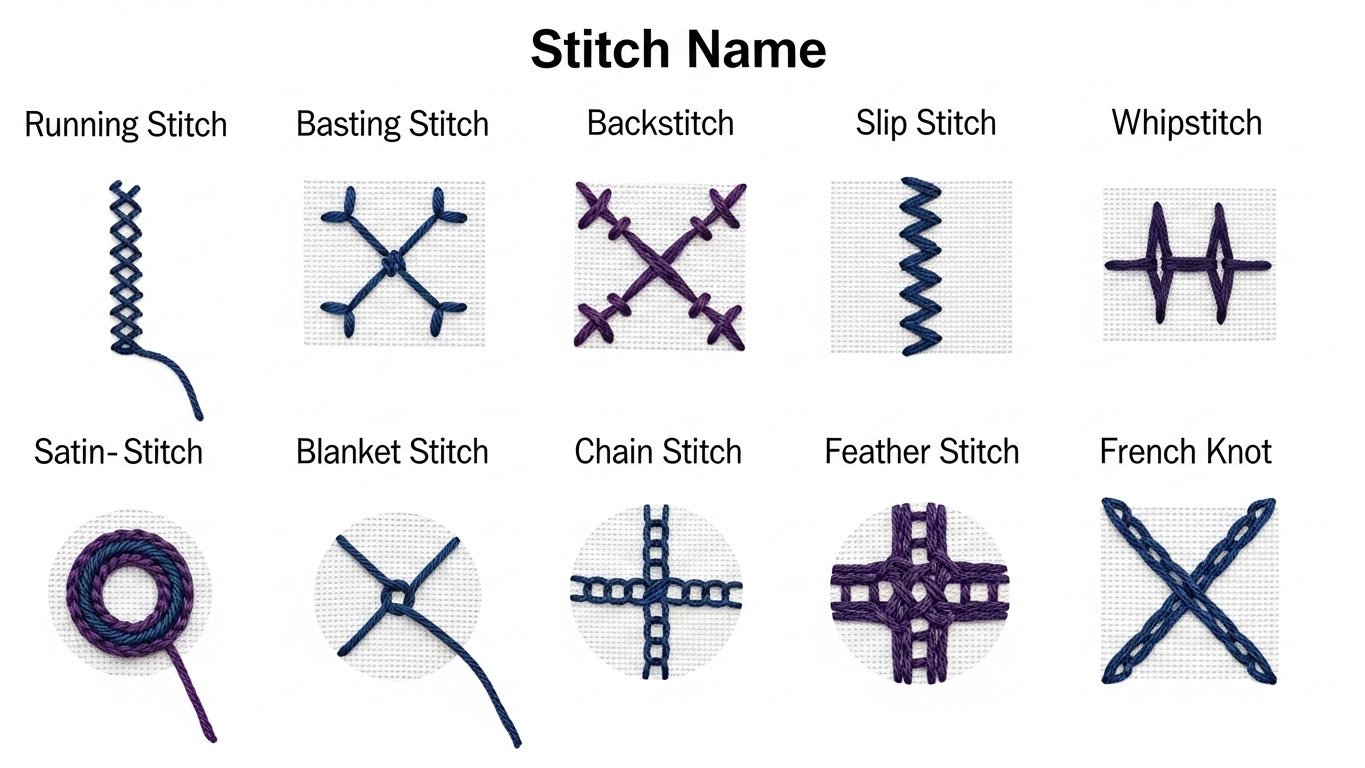

Nahttypen, or types of stitches, form the backbone of sewing. Whether you’re a seasoned seamstress or just starting out on your crafting journey, understanding different stitch types is essential. Each stitch has its own personality and purpose, transforming fabric into something extraordinary. From basic seams that hold your garment together to intricate decorative stitches that add flair to your projects, the variety can be overwhelming yet exciting.

Imagine infusing life into your creations with every single thread you weave! In this guide, we’ll explore everything from fundamental stitches to fancy embellishments. Get ready to dive deep into the world of Nahttypen and elevate your sewing game like never before!

Basic Stitches

Basic stitches form the foundation of sewing. They are essential for both beginners and seasoned crafters alike.

The straight stitch is perhaps the most fundamental. It’s versatile, perfect for seams, hems, and repairs. You can use it by hand or with a machine.

Next up is the zigzag stitch. This one prevents fraying and adds elasticity to your seams. It’s ideal for knit fabrics or finishing raw edges.

Another important type is the backstitch. It creates strong seams, making it great for heavier materials like denim. The technique involves stitching backwards to reinforce your work.

Don’t forget about the basting stitch! This temporary stitch holds fabric pieces together before you commit to permanent stitching.

Master these basic stitches, and you’ll be well on your way to tackling more complex projects with confidence!

Decorative Stitches

Decorative stitches add flair and personality to your sewing projects. They transform simple seams into eye-catching designs that showcase your creativity.

One popular type is the zigzag stitch, perfect for finishing edges while providing a stylish touch. This versatile stitch can be adjusted in width and length, allowing it to fit various fabrics and styles.

Another favorite is the satin stitch, often used for appliqués. Its smooth finish gives depth to shapes, making them pop against their background.

For those who enjoy intricate patterns, consider using decorative embroidery stitches like chain or feather stitches. These can turn plain fabric into stunning art pieces with just a few thoughtful applications.

Experimenting with colors also enhances the visual appeal of these stitches. Bright threads against neutral backgrounds create striking contrasts that draw attention without overwhelming the overall design.

Hand Stitches vs Machine Stitches

When it comes to stitching, the choice between hand and machine stitches can shape your project’s outcome. Hand stitches offer a personal touch. They allow for greater control over details and create unique textures that machines sometimes can’t replicate.

On the other hand, machine stitches are all about speed and efficiency. With modern machines, you can complete projects in a fraction of the time. The consistency in tension ensures even results across seams.

Hand stitching may be beneficial for delicate fabrics or intricate designs where precision is vital. It lends itself well to heirloom pieces that tell a story through their craftsmanship.

Machine stitching excels when durability is required, especially for everyday items like clothing or bags. Consider the nature of your project carefully before deciding on your preferred method. Each option has its strengths tailored to different needs and styles.

Choosing the Right Stitch for Your Project

Choosing the right stitch can transform your project from ordinary to extraordinary. Start by considering the fabric type. Lightweight fabrics often require delicate stitches, while heavier materials may need more robust options.

Think about the purpose of your project as well. If you’re sewing garments that will undergo frequent movement, opt for stretchy stitches like a zigzag or stretch stitch. For home decor items, straight and decorative stitches can add character without compromising durability.

Don’t forget about aesthetics! Decorative stitches can elevate simple seams into statement pieces. Experiment with different thread colors to create visual interest.

Always keep in mind the ease of use. Some stitches are simpler to execute than others—especially for beginners. So choose wisely based on both skill level and desired outcome; it makes all the difference in your stitching journey!

Common Mistakes to Avoid

One common mistake in sewing is choosing the wrong type of stitch for your fabric. Lightweight materials require delicate stitches, while heavier fabrics need sturdier ones. Ignoring this can lead to tearing or puckering.

Another frequent error is neglecting seam allowances. Always measure and cut accurately to prevent fraying and ensure durability.

Many sewists also forget about thread tension. Incorrect tension settings can cause loose or overly tight seams, which compromise the overall look of your project.

Don’t skip pressing as you sew either. This simple step helps set stitches properly and gives a professional finish to your work.

Avoid rushing through projects. Taking time allows for better precision and fewer mistakes, leading to a more satisfying end result that showcases your skills beautifully.

Tips for Perfecting Your Stitches

Perfecting your stitches takes practice and patience. Start by choosing the right needle for your fabric. A compatible needle ensures smoother stitching.

Adjust your tension settings on the sewing machine. Too tight or too loose can ruin the look of your work. Experiment to find that sweet spot.

Use high-quality thread. It makes a noticeable difference in both durability and appearance. Cheap thread can break easily, leading to frustration.

Don’t forget about lighting! Proper illumination helps you see every detail clearly, minimizing mistakes.

Practice regularly on scrap fabric before diving into your main project. This builds confidence and hones your technique without pressure.

Keep everything organized—tools within reach prevent distractions and ensure a more enjoyable sewing experience.

Conclusion

Understanding the different Nahttypen is crucial for anyone looking to enhance their sewing skills. Whether you’re working on a simple project or something more intricate, selecting the right stitch can make all the difference in quality and appearance.

With basic stitches forming the foundation of your work and decorative stitches adding charm, there’s a world of possibilities at your fingertips. Choosing between hand and machine stitches depends on your specific needs, while avoiding common mistakes will save you time and frustration.

Perfecting your technique takes practice but pays off significantly in finished projects that look polished. So explore various types of stitches, experiment with them, and let creativity guide you as you sew!

Blog

How OEM Manufacturing Helps Baby Stroller Brands Control Costs Without Compromising Quality

The baby stroller market is highly competitive, with brands constantly balancing quality, safety, and pricing. Parents expect strollers to be safe, comfortable, and durable, but they also compare prices carefully before making a purchase. For brands, this creates a challenge: how to maintain high manufacturing standards while keeping production costs under control.

OEM manufacturing has become a practical solution for stroller brands facing this challenge. By partnering with experienced manufacturers, brands can optimize production costs without sacrificing product reliability or safety. This approach allows businesses to remain competitive while meeting modern parenting expectations.

The Cost Challenges Faced by Baby Stroller Brands

Producing baby strollers involves multiple cost factors, including materials, labor, tooling, testing, and logistics. Managing all these elements in-house can quickly increase expenses, especially for growing brands or companies entering new markets.

Common cost-related challenges include:

- High investment in machinery and production facilities

- Rising material and labor costs

- Inefficient production processes

- Limited purchasing power for raw materials

- Difficulty scaling production efficiently

OEM manufacturing helps address these challenges by offering structured production systems designed for efficiency.

Understanding How OEM Manufacturing Reduces Production Costs

OEM manufacturers operate specialized facilities that focus on baby products and mobility equipment. Because these manufacturers serve multiple brands, they can spread operational costs across larger production volumes.

This shared efficiency allows brands to benefit from:

- Optimized production workflows

- Bulk material sourcing at lower prices

- Reduced waste through standardized processes

- Lower overhead compared to in-house manufacturing

As a result, brands gain access to professional manufacturing without bearing the full cost burden themselves.

Material Optimization Without Sacrificing Safety

Material selection plays a major role in stroller cost and performance. Choosing the right materials can significantly affect both pricing and product durability. OEM manufacturers have experience selecting materials that balance cost efficiency with safety and strength.

For example, manufacturers may recommend lightweight alloys that provide durability without unnecessary weight or cost. Similarly, they can guide brands toward fabrics that meet safety standards while remaining cost-effective and long-lasting.

An experienced baby stroller OEM manufacturer uses this expertise to help brands make informed decisions that support both quality and budget goals.

Efficient Design Engineering to Avoid Costly Errors

Design errors during early development stages can lead to expensive revisions later. OEM manufacturing partners help brands avoid these mistakes by reviewing designs for manufacturability before production begins.

Through engineering analysis and prototype testing, manufacturers identify potential issues such as weak joints, inefficient folding mechanisms, or unnecessary complexity. Addressing these concerns early reduces rework, saves time, and lowers overall production costs.

This proactive approach ensures smoother production and fewer delays.

Streamlined Production Processes and Labor Efficiency

OEM manufacturers invest in optimized production lines and trained labor teams. This efficiency allows them to produce strollers with consistent quality while minimizing labor costs.

Standardized workflows ensure that each production step is performed accurately and efficiently. Automation, where appropriate, further reduces manual errors and speeds up assembly.

For brands, this means:

- Faster production timelines

- Lower labor-related expenses

- Consistent product quality

- Predictable delivery schedules

These advantages are difficult to achieve without specialized manufacturing infrastructure.

Reducing Costs Through Scalable Production

One of the key benefits of OEM manufacturing is scalability. As order volumes increase, production costs per unit often decrease due to economies of scale. OEM partners are equipped to handle both small and large production runs efficiently.

Scalable production helps brands:

- Respond to growing market demand

- Reduce per-unit manufacturing costs

- Maintain consistent quality at higher volumes

- Plan long-term pricing strategies

This scalability supports sustainable growth while protecting profit margins.

Quality Control as a Cost-Saving Measure

While quality control may seem like an added expense, it actually helps reduce costs in the long run. Defective products lead to returns, recalls, and reputational damage—all of which are costly.

OEM manufacturers implement multi-stage quality inspections to catch issues early. These checks ensure that strollers meet safety and performance standards before shipment, reducing the likelihood of post-sale problems.

Strong quality control protects both brand reputation and financial stability.

Logistics and Supply Chain Optimization

OEM manufacturing partners often assist with logistics planning and supply chain coordination. Efficient packaging, shipment consolidation, and optimized transportation routes help reduce overall logistics costs.

By leveraging established supply networks, manufacturers help brands avoid delays and unexpected expenses. This coordination ensures that products reach distributors or retailers on time and within budget.

Cost Transparency and Long-Term Planning

Reliable OEM partners provide clear cost breakdowns and transparent pricing structures. This transparency allows brands to plan budgets accurately and make informed decisions about product development and pricing.

Open communication about costs also helps brands identify areas for future optimization, such as material alternatives or production adjustments.

OEM Manufacturing as a Strategic Cost-Control Tool

OEM manufacturing is not just about reducing expenses—it is about creating a sustainable cost structure that supports long-term growth. Manufacturers with industry experience can suggest design improvements, material substitutions, or production methods that enhance efficiency over time.

Brands that work with a trusted baby stroller OEM manufacturer gain access to this strategic support, helping them remain competitive in a price-sensitive market.

Supporting Brand Value While Managing Costs

Cost control should never come at the expense of brand value. Parents associate stroller quality with safety and care, making it essential to maintain high standards. OEM manufacturing enables brands to manage costs while delivering products that meet consumer expectations.

Companies such as bebluxbaby.com support stroller brands with structured OEM and ODM solutions designed to balance quality, efficiency, and affordability.

Adapting to Market Changes Through Flexible Manufacturing

Market conditions, material prices, and consumer preferences can change quickly. OEM manufacturing partners offer flexibility that helps brands adapt without major disruptions.

Whether adjusting production volumes or updating designs, flexible manufacturing ensures brands can respond to change while keeping costs under control.

Conclusion

Managing production costs without compromising quality is one of the biggest challenges for baby stroller brands. OEM manufacturing provides a practical solution by offering efficient production systems, material expertise, and scalable operations.

By partnering with experienced manufacturers, brands can optimize costs, protect product quality, and build sustainable growth strategies. In a competitive market where parents expect both value and reliability, OEM manufacturing remains a key factor in long-term success.

Blog

Eczedone: Revolutionizing eczema treatment

Eczema affects millions of people worldwide, causing discomfort and frustration. For those living with this skin condition, finding an effective treatment can feel like searching for a needle in a haystack. Enter Eczedone—a revolutionary solution that promises to change the game for eczema sufferers everywhere. Imagine a product that not only alleviates symptoms but also promotes healing from within. Eczedone is making waves in the skincare community, garnering attention for its unique approach to treating eczema. If you’re tired of battling inflamed skin and endless itching, it’s time to dive into how this innovative treatment could be your new best friend on the road to relief!

What is Eczedone and how does it work?

Eczedone is a cutting-edge topical treatment designed specifically for eczema relief. Its formulation combines potent natural ingredients with advanced scientific research, targeting the root causes of skin irritation.

At its core, Eczedone works by restoring the skin’s barrier function. This helps lock in moisture while keeping irritants at bay. The blend of soothing botanicals calms inflammation and reduces redness, providing quick relief from itching.

Moreover, Eczedone promotes skin regeneration. By encouraging cell turnover, it aids in healing damaged areas more rapidly than conventional treatments can achieve.

Users often report an immediate sense of comfort upon application due to its lightweight texture and fast absorption. Unlike many products that leave a greasy residue, Eczedone fits seamlessly into daily skincare routines. It represents a significant advancement in how we approach eczema management today.

The History of Eczema Treatment

Eczema has troubled humanity for centuries. Ancient civilizations turned to natural remedies, using ingredients like honey and olive oil to soothe irritated skin.

In the Middle Ages, herbal concoctions gained popularity. People relied on plant-based treatments that were thought to possess healing properties. However, medical understanding was limited during this time.

The 19th century marked a shift toward more scientific approaches. Dermatologists began identifying eczema as a distinct condition rather than just an annoying rash. This led to innovations in topical treatments containing coal tar and corticosteroids.

As research progressed into the late 20th century, new therapies emerged. Moisturizers became essential in managing symptoms while antihistamines helped control itching.

Fast forward to today—treatment options continue evolving with advanced medications and targeted therapies that address root causes of eczema rather than just alleviating symptoms. The journey is ongoing, driven by a commitment to improve quality of life for those affected by this chronic condition.

The Benefits of Eczedone

Eczedone offers a new hope for those battling eczema. Its unique formulation targets inflammation, providing relief from itching and discomfort.

This breakthrough treatment is designed to restore the skin’s natural barrier. Hydration levels improve significantly, helping to soothe irritated areas.

Users report faster healing times. The active ingredients work synergistically to reduce redness and promote cell regeneration.

Unlike many traditional treatments, Eczedone has fewer side effects. This makes it suitable for long-term use without the worry of complications or dependency.

Many users appreciate its lightweight texture. It absorbs quickly and leaves no greasy residue, making daily application a breeze.

Additionally, Eczedone is formulated with natural extracts that nourish the skin while addressing eczema symptoms. People find this dual-action approach refreshing in an often-overwhelming skincare market.

Success Stories and Testimonials from Users

Eczedone has changed lives for many who struggled with eczema. Sarah, a mother of two, shared how she battled flare-ups for years. After trying Eczedone, her skin became clearer and softer within weeks.

Mark found relief after months of discomfort. He described feeling hopeless until he discovered this product. Now his confidence is back, and he no longer hides under long sleeves.

Testimonials flood in from users raving about the soothing effects of Eczedone. Many highlight its non-greasy formula that absorbs quickly without leaving residue behind.

Users appreciate not just the physical relief but also the emotional boost that comes from improved skin health. With each story echoing similar themes of hope and renewal, it’s clear that Eczedone resonates deeply with those seeking effective eczema management.

Comparison to Other Eczema Treatments

When exploring eczema treatments, many options flood the market. Topical steroids and immunomodulators have been traditional go-tos for managing flare-ups. While effective, they often come with side effects like thinning skin or increased risk of infections.

Eczedone stands apart from these conventional treatments. It focuses on nourishing the skin barrier rather than suppressing inflammation. This unique approach helps to heal the underlying issues that contribute to eczema flare-ups.

Unlike systemic medications that can affect your entire body, Eczedone targets only affected areas. Users report fewer side effects compared to steroid-based solutions, making it a more appealing option for long-term use.

Natural remedies also exist but often lack scientific backing or consistency in results. Eczedone combines natural ingredients with clinical research, providing a solid foundation for its efficacy and safety in treating eczema symptoms effectively.

How to Incorporate Eczedone into Your Skincare Routine

Incorporating Eczedone into your skincare routine is straightforward. Start by cleansing your skin with a gentle, fragrance-free cleanser. This will help prepare your skin to absorb the treatment effectively.

After cleansing, apply a thin layer of Eczedone directly onto the affected areas. Use it twice daily for optimal results. Gently massage it in until fully absorbed; this helps enhance its effectiveness.

Follow up with a suitable moisturizer that complements Eczedone’s hydrating properties. Look for products rich in ceramides or hyaluronic acid to lock in moisture and support barrier repair.

If you use other treatments or active ingredients, space them out throughout the day to avoid irritation. Always perform a patch test when introducing new products into your regimen.

Stay consistent and observe how your skin responds over time, adjusting usage as needed based on feedback from your body.

Conclusion: Is Eczedone the Future of Eczema Treatment?

Eczedone is making waves in the world of eczema treatment. With its innovative formulation and focused approach to skin health, it’s capturing the attention of both users and experts alike. The buzz surrounding Eczedone stems from its unique ability to target inflammation, soothe irritated skin, and provide lasting hydration.

The stories shared by those who have used Eczedone highlight its potential as a game-changer for many struggling with this chronic condition. Users report significant improvements in their symptoms, which contributes to higher confidence levels and a better quality of life.

As more people begin to incorporate Eczedone into their skincare routines, it will be interesting to see how it stands up against traditional treatments over time. While some may still prefer established methods, others are eager for alternatives that promise real change without harsh side effects.

The future looks promising for Eczedone as ongoing research could lead not only to greater understanding but also further advancements in eczema care. It seems we are at the beginning of an exciting chapter in treating eczema where new options like Eczedone take center stage alongside traditional therapies.

Blog

35% weight reduction miracle How aluminum CNC turning is reshaping the performance of outdoor equipment.

Introduction

Outdoor equipment manufacturers face the critical challenge of balancing durability with minimal weight. Traditional methods like casting often fail to optimize this balance due to suboptimal material selection and insufficient machining precision, leading to performance limitations. Aluminium CNC turning technology provides a definitive solution by leveraging high-precision machining and material science. It produces components that are exceptionally light and strong, effectively redefining standards for bespoke gear manufacturing.

What is Aluminium CNC Turning, and Why is it Indispensable in Bespoke Gear Manufacturing?

Aluminium CNC turning is a subtractive manufacturing process where a computer-controlled lathe rotates an aluminium bar stock at high speeds while a precision cutting tool shapes it. This method is fundamental to modern precision machining, producing parts with exceptionally tight tolerances and high repeatability directly from a digital model.

Its indispensability in bespoke gear manufacturing stems from three key advantages. Firstly, it enables true customization, allowing for the production of unique, complex components tailored to specific applications without the need for expensive tooling. Secondly, the process is highly material-efficient. By removing material only where necessary, it significantly reduces waste compared to traditional methods, aligning with sustainable manufacturing principles and lowering material costs.

According to the ASM International Handbook on material science, aluminium alloys offer an exceptional strength-to-weight ratio, corrosion resistance, and machinability. Aluminium CNC Turning allows engineers to fully exploit these properties. It enables the creation of sophisticated features like thin walls and internal reinforcement structures that are impossible with other methods, achieving the ideal equilibrium between lightness and strength required for high-performance custom gear.

How to Choose the Right Aluminium Alloy for CNC Fabrication Adventures?

For equipment in CNC fabrication adventures, proper material selection is critical to avoid field failures. Common options for aluminium CNC turning parts include CNC 6061 aluminum and the 7075 series. CNC 6061 aluminum is a versatile, cost-effective choice, offering an excellent balance of strength, machinability, corrosion resistance, and weldability in the T6 condition, ideal for brackets, housings, and frames. The 7075 series provides superior strength, rivaling steel while remaining lightweight, perfect for high-stress components like carabiners or drone parts.

However, it has lower corrosion resistance than 6061, often requiring protective treatments, and is more challenging and costly to machine. Material selection should follow international standards, such as those fromISO, to ensure consistency, verified properties, and reliable performance in demanding environments, guaranteeing quality assurance for critical parts.

How Does Aluminium CNC Turning Achieve Breakthroughs in Real CNC Project Stories?

The theoretical benefits of Aluminium CNC turning are best validated through tangible CNC project stories. These narratives illustrate how the technology solves real-world engineering challenges.

Project Challenge: Ultralight Expedition Drone

A manufacturer of long-range expedition drones needed to extend flight time for aerial mapping. The primary constraint was the weight of the aircraft’s core frame, which limited battery capacity and agility.

Technical Solution: Topology Optimization and Precision Machining

The engineering team utilized generative design software to create a highly efficient, organic frame structure that minimized mass while maintaining stiffness. This complex design was then manufactured from 7075 aluminium using advanced 5-axis Aluminium CNC Turning and milling centers. For a deeper dive into the technical specifics of this process, one can explore this detailed guide on the Aluminium CNC Turning process.

Documented Results and Impact

The new frame achieved a 35% weight reduction, directly translating into a 25% increase in flight time and markedly improved handling characteristics.

The high-precision aluminum CNC service ensured that every unit produced was identical, streamlining assembly and enhancing overall product reliability for the client.

This case exemplifies how CNC Project Stories demonstrate the practical application of aluminium CNC turning parts in creating superior, market-leading products.

What are the Key Technologies for High-Quality aluminiumCNC turning parts?

Producing reliable, high-performance custom CNC aluminum components requires more than just a machine; it hinges on a suite of critical technologies and rigorous processes.

Precision machining expertise is the cornerstone. This includes the selection of appropriate tooling (e.g., diamond-tipped tools for fine finishing), optimization of cutting parameters (speed, feed rate, depth of cut), and the effective application of coolants to manage heat. For delicate or complex aluminium CNC turning parts, sophisticated workholding and toolpath strategies are essential to prevent vibration and thermal deformation, ensuring consistent adherence to tolerances as tight as ±0.005 mm.

Quality assurance systems provide the foundation for trust. A reputable aluminum CNC machining serviceprovider will hold international certifications like ISO 9001 (Quality Management) and AS9100D (Aerospace Quality). These frameworks guarantee traceability and strict process control from raw material inspection to final part verification, ensuring that every custom CNC aluminum component meets its specifications.

From a cost perspective, these technologies collectively enhance value. By minimizing scrap rates, reducing cycle times, and extending tool life, they optimize the entire manufacturing process, making even low-volume custom CNC aluminum projects economically viable without sacrificing quality.

Future Trends: How will CNC Fabrication Adventures Drive Innovation in Bespoke Gear Manufacturing?

The convergence of CNC fabrication adventures and bespoke gear manufacturing is poised for significant evolution, driven by technological advancements and shifting consumer expectations.

The Rise of the Digital Thread

The future lies in the seamless integration of design, simulation, and production data. Artificial intelligence will optimize machining parameters in real-time and predict maintenance needs, ensuring every aluminium CNC turning part is produced under ideal conditions. Digital twin technology will allow for virtual testing and iteration, drastically reducing development cycles for adventure gear.

Sustainability and Hyper Personalization

The use of recycled aluminium alloys, combined with the inherent material efficiency of Aluminium CNC Turning, will minimize the environmental footprint of production. This green manufacturing approach will become a standard expectation for brands.

As aluminum CNC service becomes more accessible, customization will extend beyond function to form. Gear will be tailored not just for performance but also for individual ergonomics and aesthetic preferences, becoming true extensions of the user.

To explore how these future-forward capabilities can be applied to your next project, consider partnering with a provider that offers comprehensive aluminum CNC machining service.

Conclusion

In summary, aluminium CNC turning has effectively addressed the historical trade-off between weight and strength in outdoor equipment manufacturing. Through the application of precision machining and intelligent material selection, it provides a superior solution for bespoke gear manufacturing, as evidenced by compelling CNC project stories.

For those seeking to develop the next generation of high-performance outdoor equipment, partnering with an expert manufacturer is the next logical step. If you are looking for a reliable, precision-driven partner to bring your innovative designs to life, contact a specialist team today to discuss a custom solution for your product.

Author Biography

The author is a precision manufacturing specialist with over a decade of experience focused on CNC technologies and material science. The team at JS Precision operates with a commitment to excellence, underpinned by ISO 9001, IATF 16949, AS9100D, and ISO 14001 certifications, ensuring every project meets the highest international standards.

FAQ

Q1: What level of precision can typically be achieved with Aluminium CNC Turning?

A1: This technology can hold tolerances as tight as ±0.005 mm, ensuring the dimensional stability and consistency required for critical adventure gear components.

Q2: How durable is CNC 6061 aluminum in outdoor environments?

A2: 6061 aluminium offers good inherent corrosion resistance. This can be significantly enhanced through surface treatments like anodizing, which creates a hard, protective layer, extending the component’s life in harsh conditions.

Q3: How is the cost-effectiveness of an aluminum CNC service evaluated?

A3: Cost is influenced by material volume, part complexity, and order quantity. Employing Design for Manufacturability (DFM) principles to simplify geometry can reduce machining time and cost while maintaining quality.

Q4: Do custom CNC aluminum parts support low-volume production?

A4: Yes, CNC machining is ideal for low-volume and prototype orders. It does not require custom tooling, allowing for cost-effective production of small batches and rapid design iterations.

Q5: What is the unique advantage of Precision Machining in Bespoke Gear Manufacturing?

A5: It enables the fabrication of complex, lightweight geometries that enhance functionality and integration. Combined with stringent quality control, it results in highly personalized, reliable gear with reduced failure rates.

-

Blog2 months ago

Blog2 months agoWhat Is i̇ns? Exploring Its Origins, Usage, and Symbolism

-

Blog3 months ago

Blog3 months agoJememôtre: A Hidden Gem in the World of Culture

-

Technology2 months ago

Technology2 months agoCartetach: The Next Big Thing in Digital Communication

-

Technology1 month ago

Technology1 month ago100GBASE-ZR4 Optical Modules: A Practical Long-Reach Solution for Modern Data Center Interconnects

-

Technology2 months ago

Technology2 months agoRgarrpto: Understanding Its Impact on Modern Technology

-

Blog2 months ago

Blog2 months agoHormita: Understanding the Meaning, Uses, and Digital Importance of a Rising Keyword

-

Life Style2 months ago

Life Style2 months agoTaylor Breesey Face Reveal: Everything Fans Need to Know

-

Blog2 months ago

Blog2 months agoLeBron James Oenis: Inside the Media Hype and Personal Rumors